Details:

A restructuring of their farms, driven by a need to increase their irrigation capabilities required the client to instigate the Farm Irrigation Pump Stations project involving expanding an existing Irrigation pump station as well as building a new pump station.

SPL were contracted to provide a turn-key solution for the entire project involving:

- Civil Works - including Geotech Ground Testing, Earthworks, Piling, Silo Foundation Design & Build, Pump Station Foundation Design & Build and building the workshop, control room & MCC,

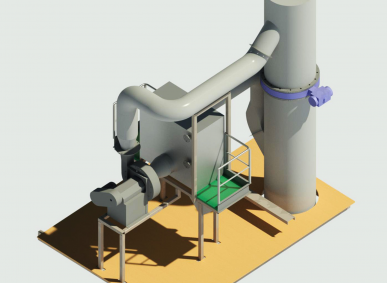

- Silo Supply & installation,

- Mechanical Design, Fabrication & Installation,

- Electrical Design & Installation,

- Automation,

- Commissioning.

During the procurement phase of the project SPL worked closely with the client to reuse their existing equipment wherever possible & to ensure the supply of site preferred equipment for all new supply items.

Located on a farm, away from site, the new pump station provided the perfect setting to be run as a ring fence project, with SPL in control of inductions, H&S, contractor management & Permit to Work system. Over 4000 hrs worked without any MTIs (Medical Treatment Injuries), LTIs (Lost Time Injuries) or Environmental incidents.